Hot sale CJX2-3211 3phase 220V 50/60Hz Household Electrical AC Magnetic contactor

Product Parameter

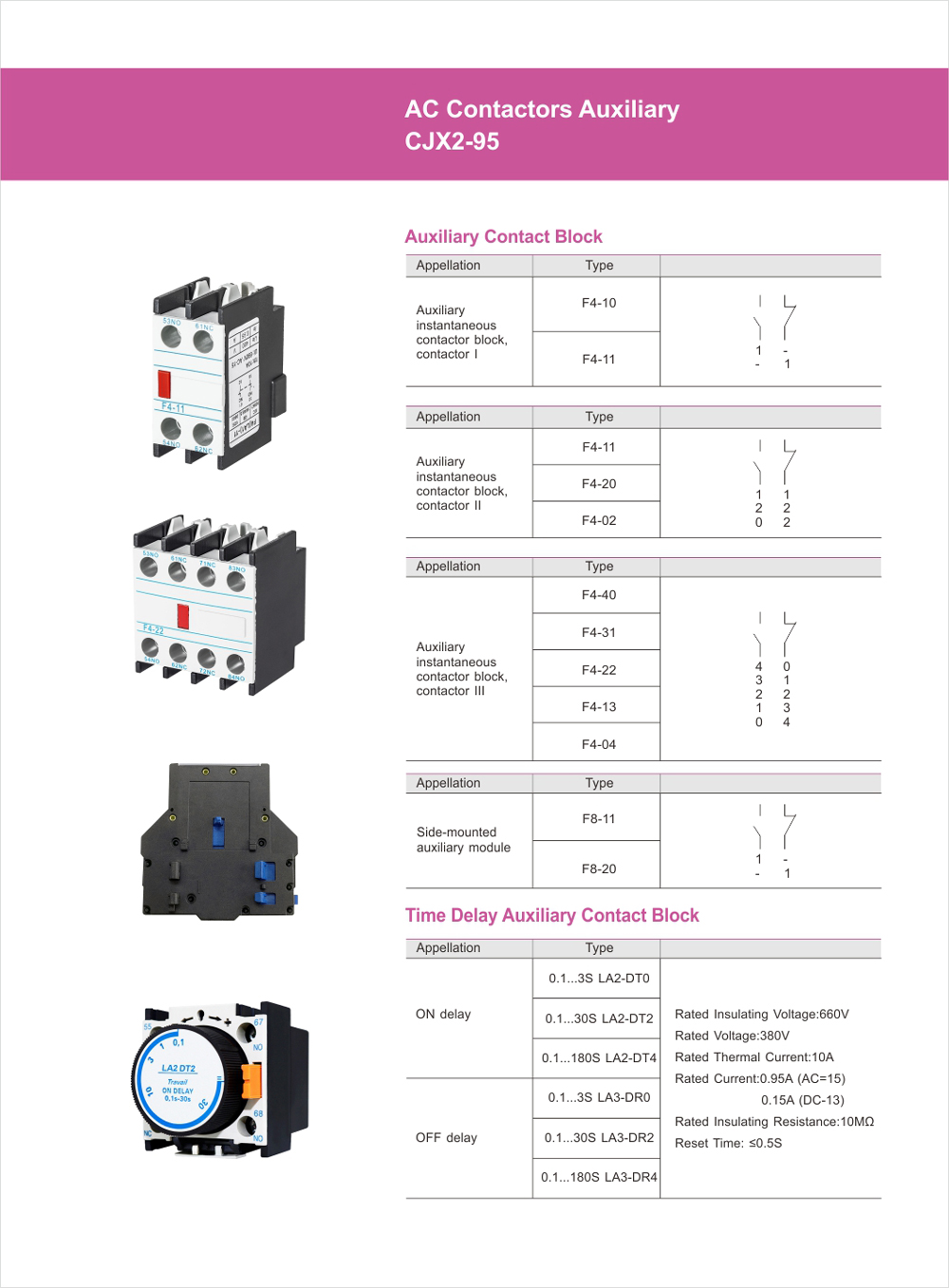

| Type | CJX2-10 | CJX2-12 | CJX2-18 | CJX2-25 | CJX2-32 | CJX2-40 | CJX2-50 | CJX2-65 | CJX2-80 | CJX2-95 | |||

| Rated working current(A) |

AC3 | 9 | 12 | 18 | 25 | 32 | 40 | 50 | 65 | 80 | 95 | ||

| AC4 | 3.5 | 5 | 7.7 | 8.5 | 12 | 18.5 | 24 | 28 | 37 | 44 | |||

| Standard power ratings of 3phase motors 50/60Hz in Category AC-3(kW) | 220/230V | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 25 | ||

| 380/400V | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | |||

| 415V | 4 | 5.5 | 9 | 11 | 15 | 22 | 25 | 37 | 45 | 45 | |||

| 500V | 5.5 | 7.5 | 10 | 15 | 18.5 | 22 | 30 | 37 | 55 | 55 | |||

| 660/690V | 5.5 | 7.5 | 10 | 15 | 18.5 | 30 | 33 | 37 | 45 | 55 | |||

| Rated Heat Current (A) |

20 | 20 | 32 | 40 | 50 | 60 | 80 | 80 | 125 | 125 | |||

| Electrical Life |

AC3 (X10⁴) | 100 | 100 | 100 | 100 | 80 | 80 | 60 | 60 | 60 | 60 | ||

| AC4 (X10⁴) | 20 | 20 | 20 | 20 | 20 | 15 | 15 | 15 | 10 | 10 | |||

| Mechanical life (X10⁴) | 1000 | 1000 | 1000 | 1000 | 800 | 800 | 800 | 800 | 600 | 600 | |||

| Number of the contacts | 3P+NO | 3P+NC+NO | |||||||||||

| 3P+NC | |||||||||||||

Standard Control Circuit Voltage

| Volts | 24 | 42 | 48 | 110 | 220 | 230 | 240 | 380 | 400 | 415 | 440 | 500 | 600 |

| 50Hz | B5 | D5 | E5 | F5 | M5 | P5 | U5 | Q5 | V5 | N5 | R5 | S5 | Y5 |

| 60Hz | B6 | D6 | E6 | F6 | M6 | - | U6 | Q6 | - | - | R6 | - | - |

| 50/60Hz | B7 | D7 | E7 | F7 | M7 | P7 | U7 | Q7 | V7 | N7 | R7 | - | - |

Environment Condition for Operation and Installation

- Ambient temperature: -5ºC~+40ºC

- Altitude: ≤2000m

- Relative humidity: The maximum temperature of 40 degrees, the air relative humidity not exceed 50%, at a lower temperature can allow for a higher relative humidity, if humidity changes as a result of occasional gel generated,should eliminate it

- Pollution level: 3

- Installation category: III

- Installation position: The installation degree of the tilt and vertical plane should not exceed ±22.5°, should be installed in place with no significant impact shaking and vibration

- Installation: The installation of fastening screws can be used,the CJX1-9~38 contactor can also be installed on 35mm standard DIN rail

Outline and Mounting Dimension(mm)

| Type | A | B | C | D | E | a | b | Φ | |||||

| CJX2-D09~12 | 47 | 76 | 82 | 113 | 133 | 34/35 | 50/60 | 4.5 | |||||

| CJX2-D18 | 47 | 76 | 87 | 118 | 138 | 34/35 | 50/60 | 1.5 | |||||

| CJX2-D25 | 57 | 86 | 95 | 126 | 146 | 40 | 48 | 4.5 | |||||

| CJX2-D32 | 57 | 86 | 100 | 131 | 151 | 40 | 48 | 4.5 | |||||

| CJX2-D40-65 | 77 | 129 | 116 | 145 | 165 | 40 | 100/110 | 6.5 | |||||

| CJX2-D80-95 | 87 | 129 | 127 | 175 | 195 | 40 | 100/110 | 6.5 | |||||

Versatile Applications of AC Contactors

introduce:

As we delve into the world of power distribution and control systems, AC contactors are one component that plays a key role in ensuring smooth electrical operation. These devices have become the backbone of numerous industries, providing reliable and efficient control for a variety of electrical applications. This article aims to clarify the multifunctional application of AC contactors and their important contribution to modern power distribution systems.

1. Industrial machinery and equipment:

AC contactors are widely used in industrial environments to control the power supply of various machinery and equipment. Whether it is a conveyor belt, a robotic arm or a high-power motor, the AC contactor acts as a switch to regulate the flow of current to achieve safe and efficient operation. By allowing or interrupting power, these contactors protect machinery from electrical damage and prevent accidents caused by sudden power surges.

2. Heating, ventilation and air conditioning (HVAC) systems:

AC contactors play an important role in HVAC systems, helping to control compressors, fans, and other electrical components. These contactors ensure that power is efficiently distributed to the appropriate equipment, allowing the HVAC system to function optimally. By regulating power flow, AC contactors help increase energy efficiency, reduce maintenance costs, and enhance the overall performance of HVAC systems.

3. Lighting control system:

In large commercial buildings, AC contactors are a key component of lighting control systems. These contactors provide centralized control of lighting circuits, allowing facility managers to automate scheduling, implement energy-saving measures, and respond to various lighting requirements. By using AC contactors, lighting systems can be effectively controlled, providing comfort, convenience and significant energy savings.

4. Renewable energy systems:

With the growing focus on renewable energy, AC contactors have found application in solar and wind turbine systems. These contactors play a key role in connecting or disconnecting these renewable energy sources to the grid or other electrical loads, ensuring safe integration and efficient use of the generated electricity. AC contactors also help protect the system from electrical faults and provide effective fault isolation when required.

5. Safety and emergency system:

AC contactors are widely used in safety and emergency systems such as fire alarms, emergency lighting and elevators. These contactors provide reliable control of connected equipment, ensuring timely response in emergency situations. By regulating power, contactors help prevent disasters and provide necessary support in critical situations, giving occupants and operators peace of mind.

in conclusion:

In conclusion, AC contactors are of great significance in modern power distribution systems in various industries. From industrial machinery and HVAC systems to lighting controls, renewable energy integration and safety applications, these devices play a key role in ensuring efficient and safe electrical operations. Their versatility, reliability, and ability to control high-power electrical loads make them indispensable components for optimal performance and safety. As technology continues to advance, the application of AC contactors is expected to further expand, contributing to a more sustainable and connected future.