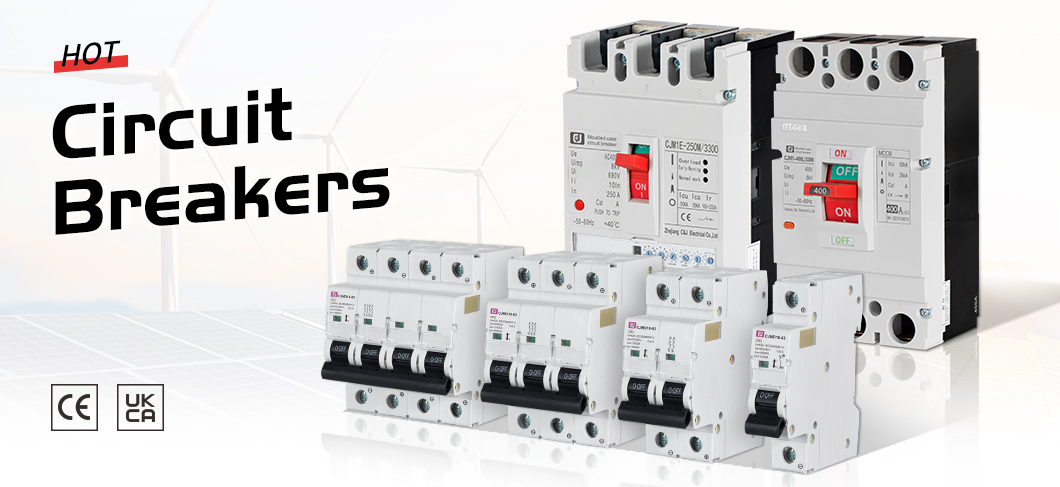

Title: Know the Difference Between Miniature Circuit Breakers and Molded Case Circuit Breakers

Circuit breakers are an essential part of a building’s electrical system. They help protect your home, office or commercial property from electrical overloads and short circuits. Two commonly used circuit breakers are the miniature circuit breaker (MCB) and the molded case circuit breaker (MCCB). Although they both serve the same purpose, there are some differences between them. In this blog, we’ll explore these differences.

1. Size and application

The main difference between MCB and MCCB is their size. As the name suggests, MCBs are smaller in size and used in low current applications up to 125 amps. They are commonly used in residential and small commercial applications. MCCBs, on the other hand, are larger and can handle higher current loads up to 5000 amps. They are typically used in industrial and commercial applications that require higher amounts of power.

2. Strong and durable

MCCB is stronger and more durable than MCB. They can handle more electrical stress and are designed to withstand harsh environments. MCCBs are usually made of a stronger material such as ceramic or molded plastic than MCBs, which are usually made of a plastic housing. MCBs are designed for use in less harsh environments and should not be exposed to highly corrosive materials or extreme temperatures.

3. Trip mechanism

Both MCBs and MCCBs are designed to trip when the current exceeds a certain limit. However, the mechanisms they use to trip are different. The MCB has a thermal magnetic trip mechanism. The mechanism uses a bimetal strip that heats up and bends when the current exceeds a threshold, causing the circuit breaker to trip. The MCCB has an electronic trip mechanism that uses a microprocessor to analyze the current flow. Once the current exceeds the threshold, the microprocessor sends a signal to the circuit breaker to trip.

4. Cost

MCBs are generally less expensive than MCCBs. This is because they are simpler in design and made of cheaper materials. They are also less durable than MCCBs and have lower current carrying capacity. MCCBs are more expensive due to their complex design and materials used, but they are more durable and can handle higher current loads.

5. Maintenance

The maintenance required for MCBs and MCCBs is very different. The MCB is simple in design and does not require much maintenance. They need to be checked regularly by an electrician and replaced if faulty. MCCBs, on the other hand, require more maintenance, such as regular inspections of electronic trip units, which may become obsolete over time and need to be replaced.

In summary, MCB and MCCB have the same function, which is to protect the electrical system from overload and short circuit. However, as we can see, there are some differences between the two. MCBs are smaller, more durable and less expensive, while MCCBs are stronger, more durable and more expensive. Application and current requirements are the main factors to consider when choosing between the two.

Post time: Jun-13-2023