1. Design and production

Design and production is an important factor to ensure the quality of metal distribution boxes, mainly involving the following two aspects:

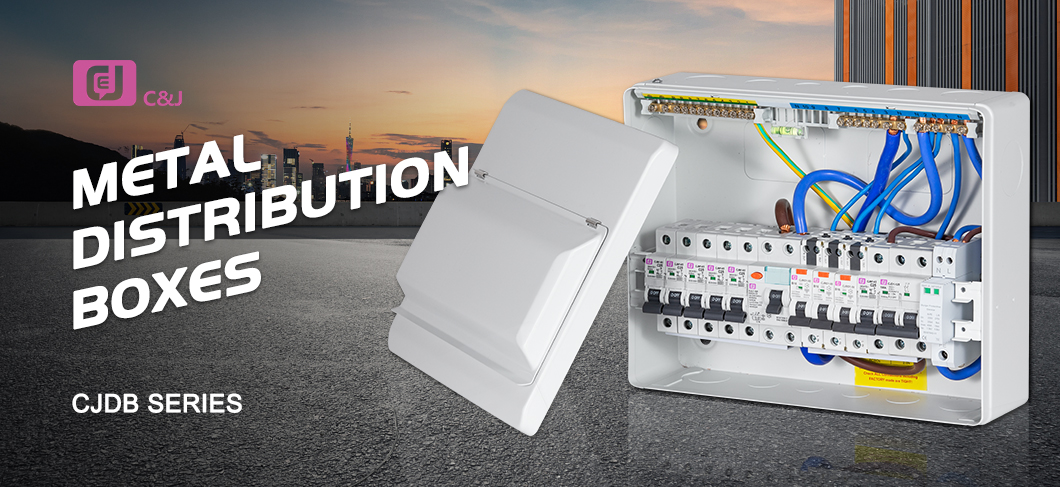

- 1.1. Design: When designing a metal distribution box, it is necessary to fully consider the required capacity, transmission power, wiring method, safety protection and other factors, and use high-strength, corrosion-resistant, and lightning-proof materials to ensure that the entire box is strong and reliable.

- 1.2. Production: The production process of metal distribution boxes includes process design, material procurement, processing and manufacturing, surface treatment, assembly and debugging. During the production process, it is necessary to process and manufacture according to the design drawings to ensure the dimensional accuracy and structural strength of each component. At the same time, surface treatment is required to prevent rust and corrosion.

2. Application scenarios

Metal distribution boxes are widely used in power supply, machinery manufacturing, communication, construction and other fields. The main application scenarios are listed below:

- 2.1. Manufacturing industry: In the industrial fields such as automobile manufacturing, machinery manufacturing, and aircraft manufacturing, metal distribution boxes are used as control panels to perform electrical control and protection on machinery and equipment.

- 2.2. Residential buildings: In residential buildings, the metal distribution box is used as a centralized control box, which can perform stable and efficient power distribution and monitoring of the power system of the entire building.

- 2.3. Large-scale transportation facilities such as railways and subways: As a power control center, the metal distribution box can perform electrical control on facilities such as the operating catenary, signal system, and signal power supply.

3. Features

Metal distribution boxes have many unique features, as follows:

- 3.1. Stability: The customized electrical circuit design inside the metal distribution box can reduce current fluctuations, thereby ensuring the stability of the power system.

- 3.2. Reliability: The metal distribution box is made of high-strength metal materials. The overall structure is compact and the protection performance is strong, which can ensure the reliable operation of power equipment in bad weather and environment.

- 3.3. Easy maintenance: The fixed structure design of the metal distribution box can facilitate the disassembly, replacement and inspection of various components, and improve the efficiency of maintenance and inspection.

- 3.4. Safety: The metal distribution box has various safety designs such as automatic power-off, leakage protection, overload protection, and over-voltage protection, which can protect the safety of electrical equipment and personnel in unexpected situations.

In the modern power system, the metal distribution box is an economical, practical, reliable and stable electrical equipment, which provides a solid guarantee for the power system in the fields of industry, construction, transportation, communication and so on.

Post time: Mar-27-2023